Solid Wood vs Engineered Wood: Which Is Better?

Choosing between solid wood and engineered wood is one of the first decisions buyers face when buying furniture. Both have real advantages — and real trade-offs. This guide breaks down the differences clearly so you can pick the right material for your budget, style, and long-term needs.

Solid wood — Furniture made from single pieces of natural timber (e.g., teak, Sheesham/Indian rosewood, mango, oak). It’s sawn and shaped from whole boards; visible grain and natural variations are norma

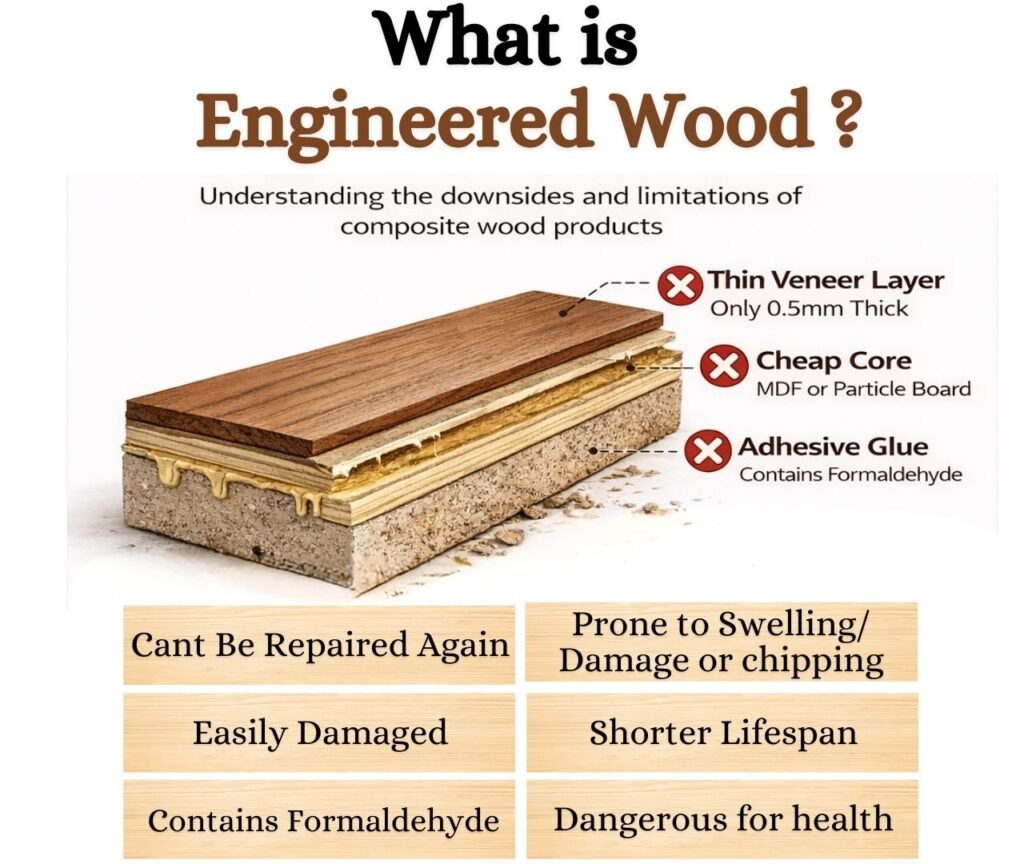

Engineered wood — Man-made panels produced by gluing wood fibers, veneers, or particles together (examples: plywood, MDF, particle board, HDF, and laminated boards). Engineered panels are often finished with laminate, veneer, or paint.

Comprehensive Comparison

1. Durability & Strength

Solid wood: Very strong; stands up well to heavy use and can be repaired or re-sanded/refinished many times. Solid hardwoods (teak, Sheesham, oak) last decades if cared for.

Engineered wood: Strength varies. Plywood is strong and stable (good for structural parts). MDF/particle board are weaker, prone to sag under heavy loads and can swell if exposed to water. Good for cabinetry where loads are controlled.

2. Stability & Warping

Solid wood: Expands and contracts with humidity. Large solid panels (e.g., big tabletops) may cup or crack in extreme conditions if not properly kiln-dried and jointed.

Engineered wood: Generally more dimensionally stable — plywood and MDF resist warping better than large solid timber panels, making them suitable for kitchens and large cabinets in humid climates.

3. Finish & Appearance

Solid wood: Unique grain patterns and natural texture. Can be oiled, waxed, or varnished; patina improves with age.

Engineered wood: Offers very uniform finishes; veneers mimic real wood grain closely and laminates give scratch-resistant surfaces. Excellent where consistency and color matching matter.

4. Cost

Solid wood: Higher cost — hardwoods and quality joinery increase price. The investment pays off over decades.

Engineered wood: More budget-friendly. Particle board is cheapest; plywood/MDF mid-range. Cost control is a major advantage for large projects.

5. Repairability & Lifespan

Solid wood: Can be repaired, patched, and refinished multiple times. Lifespan: decades to generations.

Engineered wood: Limited repair options — veneer can delaminate, particle board damaged by water is often irreparable. Lifespan: varies; well-made plywood furniture can last many years, particle board less so.

6. Weight

Solid wood: Heavier — sturdy feel but harder to move.

Engineered wood: Lighter in many cases — easier to assemble, move, and ship

7. Suitability by Furniture Type

Solid wood best for: Dining tables, solid beds, carved/chair legs, visible frames, heirloom pieces, pieces you might refinish later.

Engineered wood best for: Large flat panels (wardrobes, kitchen cabinets, bookshelves), budget bed frames, modular furniture, places where uniformity is needed.

8. Environmental Impact

Solid wood: If sourced responsibly (FSC certified or reclaimed wood), it can be sustainable. However, use of rare hardwoods without certification can be environmentally harmful.

Engineered wood: Uses wood residues and can be efficient. But watch adhesives (formaldehyde emissions) and the manufacturing footprint. Choose low-VOC/MR (marine or moisture resistant) grades when possible.